Ultra-high vacuum 3D printing

Over the past two decades, Additive Manufacturing (AM) technologies, commonly known as 3D printing, have witnessed exponential

advancements, transforming the paradigms of instrument design and fabrication across an array of scientific and engineering

disciplines. The utilization of Computer-Aided Design (CAD) and monolithic machining within the AM framework offers unprecedented

levels of flexibility, precision, and mechanical stability. These attributes not only facilitate complex geometrical constructions

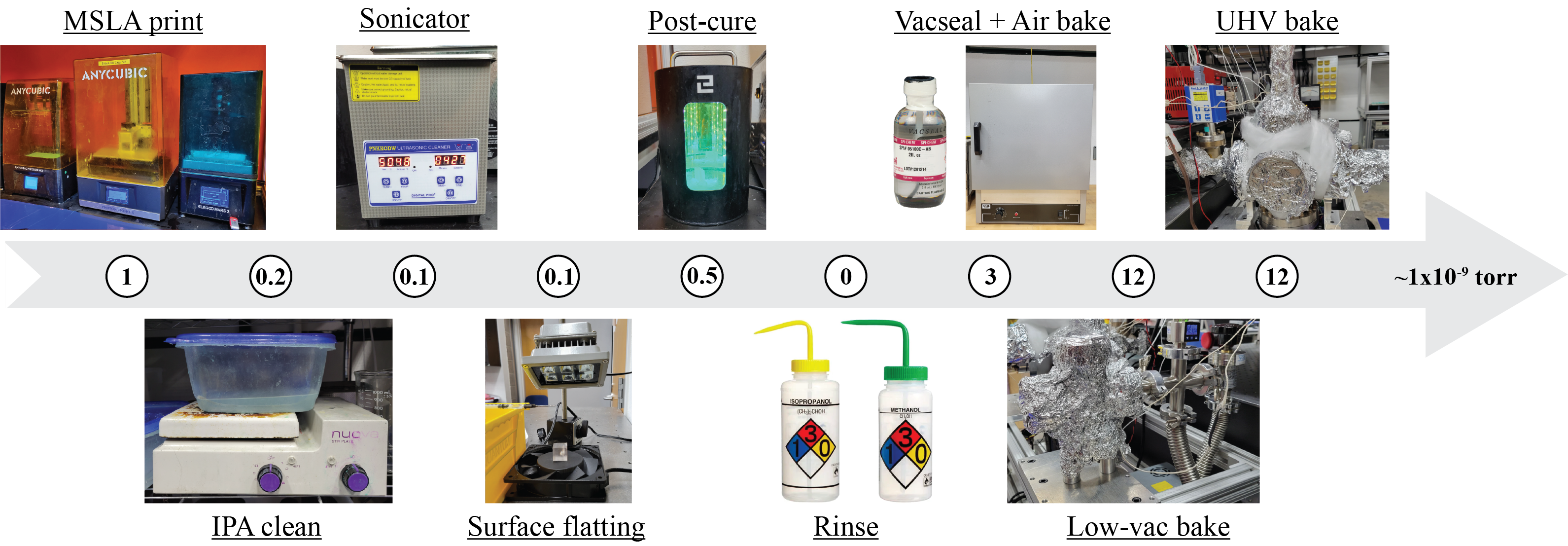

but also substantially streamline the overall fabrication workflows. In this study, we provide experimental evidence to

substantiate the viability of employing Masked Stereolithography Additive Manufacturing (MSLA) technology in concert with

commercially available photo-polymer resins for the fabrication of components that are compatible with Ultra-High Vacuum (UHV)

conditions. Utilizing high-temperature photo-polymer resins and specialized post-printing treatments—including an approximate

24-h vacuum bake—we have achieved a vacuum level of approximately 1 × 10−9 torr for a solid component encompassing a volume up

to 16 cm3. This methodology paves the way for the expedited and cost-effective production of complex, UHV-compatible devices,

thereby offering a substantial departure from conventional manufacturing techniques. The wide-ranging applicability of this

technology holds considerable potential for transformative impacts across diverse sectors of research and development. By

leveraging UHV-compatible MSLA technology, both academic researchers and industrial professionals are poised to benefit from

an efficient and adaptable fabrication methodology, consequently catalyzing cutting-edge advancements in their respective fields

of inquiry.

3D printing microwave components

Under construction...